Rebar is usually a standard steel bar or block that is certainly extensively applied in bolstered concrete and strengthened masonry constructions. These rebars typically are developed from carbon metal and could be recounted as reinforcing metal or simply reinforcement. Beneath Structural BIM Solutions Rebar detailing is usually a self-control of creating fabrication or shop drawings of metal reinforcement towards the building process. The positioning fabrication drawings that come about to be produced As outlined by design drawings for reinforcing metal are Rebar In depth drawings. Engineers and Architects make structure drawings to think of the required strengths determined by the rebar detailing that provides diameter, bar designs, portions, period of bars to aid the website for averting delays and wastage therefore dashing the whole development system.

Each individual rebar is thorough representing a form, duration, and diameter based upon the requirements with the design drawing. The Rebar placement is then shown in more element which implies the concrete cover, exact location, and Particular procedure of placement if desired. The rebar aspects and bar bending schedules may have bar diameter, bar notation, the amount of bars, pounds Together with the bars, and period of Each individual bar together with mentioning the entire bodyweight for that total listing of bars placed inside of drawing. In the preparation of rebar particulars, the inventory lengths of bars are held in see to ensure that there is no wastage from the content.

Rebar Detailing and Reinforcement concrete detailing can be modeled and coded in 3-dimension with the 3D Modelling technology like BIM Modelling Services. The specialized rebar detailing program like Rebar CAD and AutoCAD employed for this reason should help each member Using the structural engineering to arrange layouts, doc, observe, and General Command.

Acquiring recognized the elemental notion of rebar detailing a piece of structural BIM modeling, why don't we make an energy to look at the significance of it in the overall design approach is. Some in the motives are:

Significance of Rebar detailing in Structural BIM Modeling

Although second drawings and bending schedules are commonly created and presented, the 3D product can be issued to Every person they associates ranging from the consulting engineer and contractor departments right down to the steel fixers which may be within the wander out on-web page. The mixture of those two become Specifically useful for web site personnel where by web-site limits or congestion of reinforcements continue to be unknown until eventually you will find reinforcement and fixation on-internet site. For each bar, the exact situation of fixing is shown within the 3D product as well as any hindrances or obstructions.

Developing detailing reinforcements in 3D around the 2D approach is not just speedier but modeling rebar inside a three-dimensional surroundings assists take out clashes. Although modeling one can visualize if any in the bars are likely to not correct in the made a decision location, thereby determine These types of clashes while in the rebar drawings. There is even facility to evaluation the reinforcement in finish depth as a precise element illustration right before It truly is currently being ordered from the fabricator and complicated cages are assembled off-web-site.

When There is certainly the suitable rebar detailing Alternative available, a powerful and accurate reinforcement design is more info usually designed by importing structural calculations while in the structural Evaluation method. With Automation associated the variations are typically mirrored within 3D rebar detailing as well as essential updates to drawings and schedules swiftly when adjustments are made in other places in contrast to acquiring to accomplish guide variations to 2D sections and views.

In lieu of based on handbook input from paper schedules, the rebar fabricator can extract facts immediately throughout the model to the machinery. The concrete pours may be perfectly-described in the model with other facts like quantities and volumes to guarantee extra precision in controlling substance deliveries. This allows greater Manage and induce fewer wastage and reduction of General fees.

Possessing 3D detailed electronic styles will not going prohibit the principle gain having a one-phase favor that inside the engineering and detailing phase but can be utilized within the phases. Possessing reinforcement totally modeled in 3D, the contractor is assured that it will slot in spots when the time comes it to be set on-website. The data from a model can be employed from the field allowing for contractors to perform a product-based structure by using robotic complete station units together with tracking rebar and components and figuring out exactly where and when they shall be essential.

Fixers present on-website can seem within the model setting for the rebar detailing to correctly realize its software, i.e. what is needed the place and when instead of depending on their interpretation of conventional second drawings.

The structural engineers can basically in addition more speedily generate design reports, schedules, and drawings through the 3D model as as opposed with 2nd patterns, thereby maximizing style and design effectiveness. There is certainly extra accuracy in price tag projection based on the rebar quantities generated within the 3D design simply because they are additional dependable as compared to the 2D drawing just take-offs. Not merely this the quantities are wholly traceable, permitting comparisons and checks to get done simply.

Using these explanations, we can easily conclude that Rebar Detailing a willpower of Structural BIM Modelling Services is undoubtedly 1 in the crucial conditions for your personal Total good results of the project lifetime cycle. To summarize, possessing Rebar Detailing the rebar contractor can focus on creating rebars wherever there will not be any should estimate reinforcement needs for procurements at the Website on account of efficient 3D designs. The model will depict some great benefits of anchors and laps inside drawings thus making certain structure adequacy in conjunction with cutting down wastage. The overall squander and time delays are lessened at the website for the reason that most of the form drawings will often be readily available. Depending on this details the bars may be very easily fabricated according to the designs and quantity of bars expected.

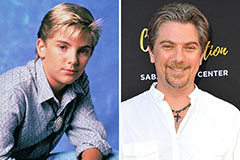

Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Jeremy Miller Then & Now!

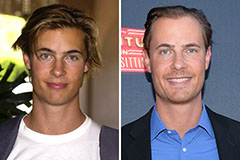

Jeremy Miller Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Susan Dey Then & Now!

Susan Dey Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!